Design

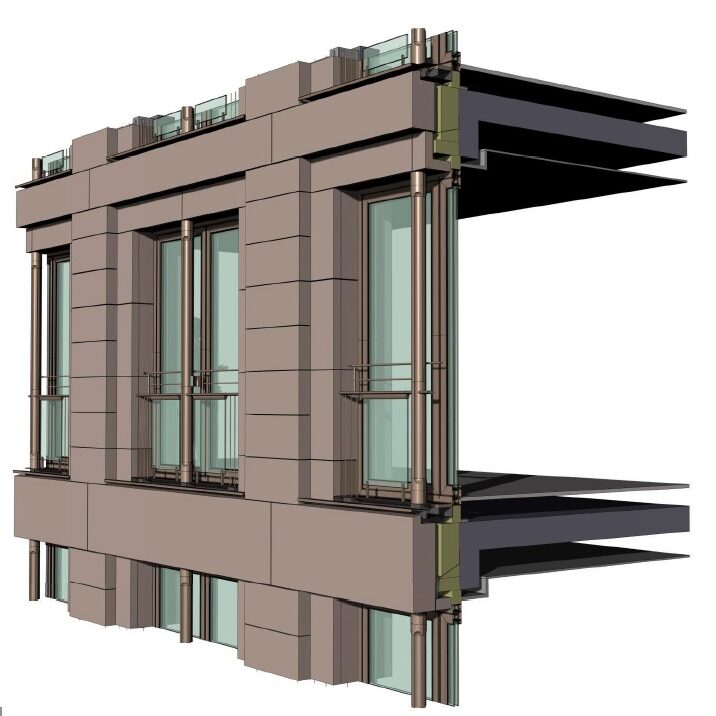

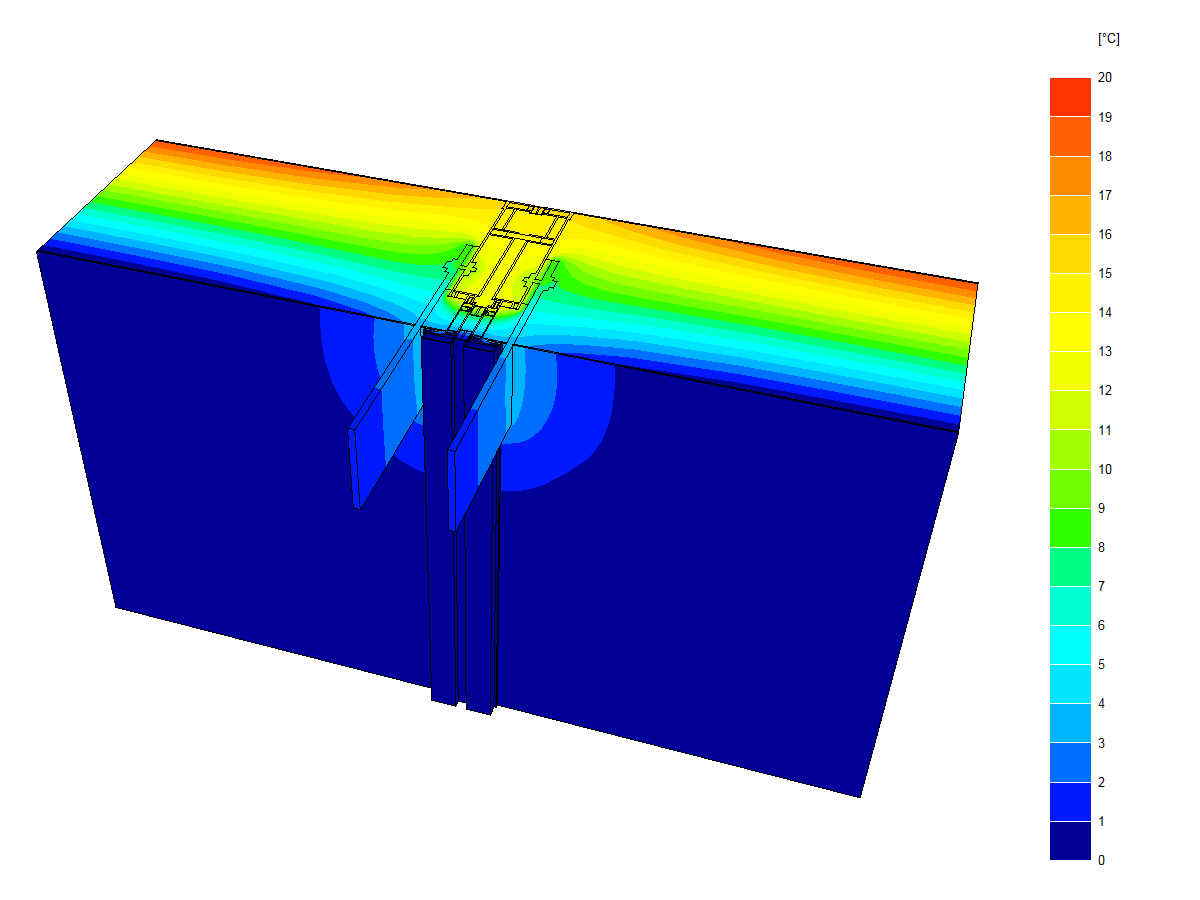

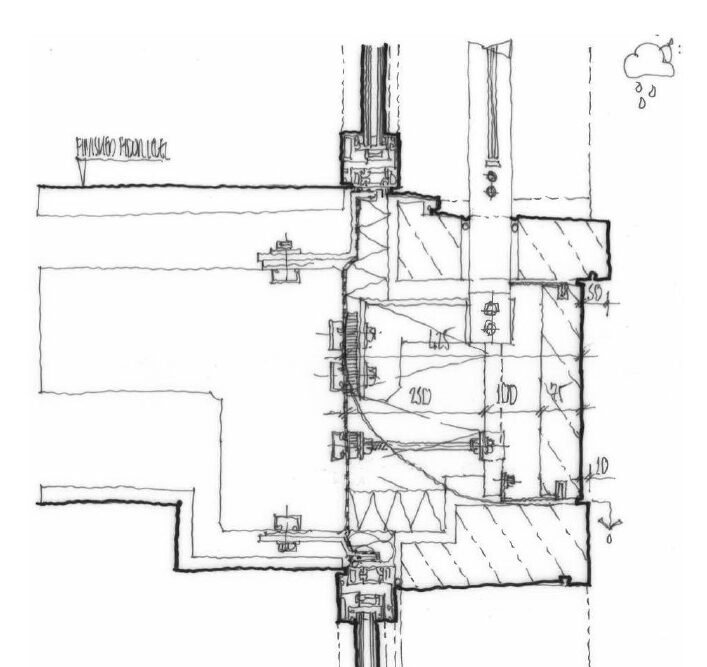

We have found that the best way to get a clear understanding of the client’s expectations is to work closely with the architect and design team, continually asking questions to help distill and clarify thinking. Our ‘design workshops’ help to explore and develop creative ideas and solutions. Our approach relies heavily on free hand sketching, allowing quick exploration of options that can be further developed in to 3D computer models or project specific CAD drawings if required.