Sustainable approach

We are living in a Climate Emergency.

The construction industry plays a crucial role in reducing global carbon emissions; a radical change of culture in the world of architecture and construction is required to achieve the level of CO2 reductions compatible with a maximum 1.5°C global temperatures rise advised by the IPCC.

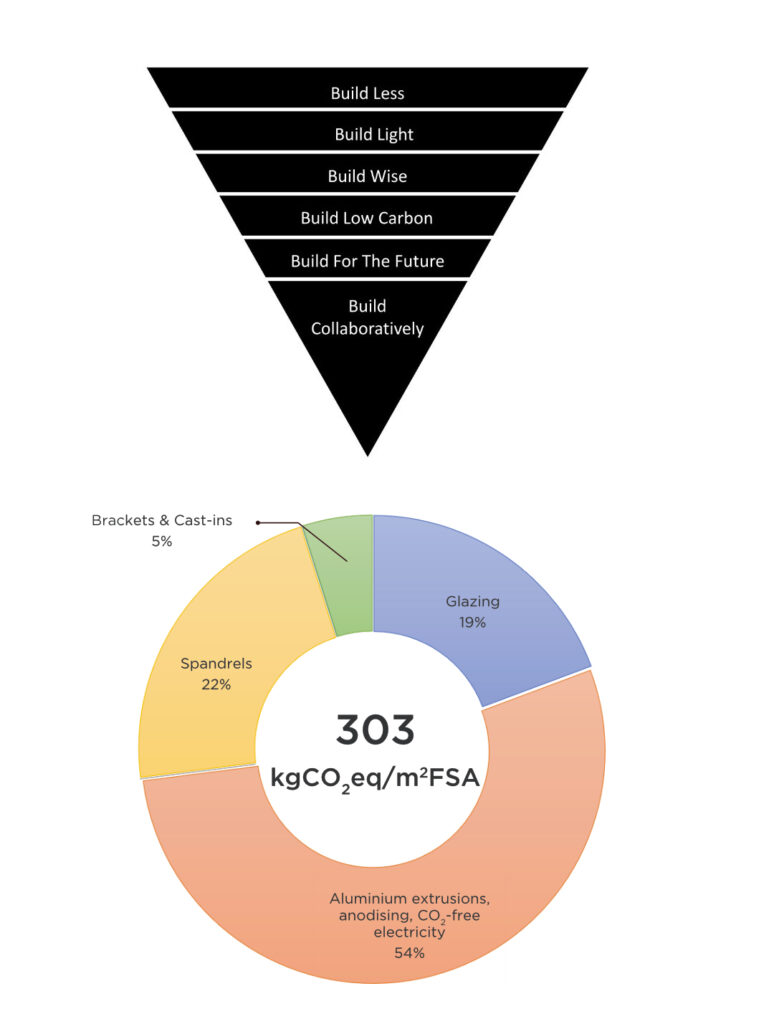

Recognising the importance of buildings’ façades in regulating operational energy, acknowledging the fundamental role of embodied carbon, and with the awareness that a ‘business as usual’ approach will not deliver the necessary savings, in recent years FMDC adopted a new design attitude where carbon is at the centre of every decision. This aligns with our clients’ sustainability agendas and the wider industry’s shift towards low carbon buildings.

Façade design for energy demand reductions

When it comes to energy modelling, in recent years we have witnessed a much welcome shift away from a simple ‘building regulation compliance’ approach to a more detailed ‘design for performance’ one. This has been supplemented by strict energy intensity targets moving towards ‘net zero’ buildings, and by the adoption of performance-based rating schemes such as NABERS.

The role of façades in reducing operational carbon is inevitably interconnected with the wider approach to a building’s energy efficiency. Regulating energy demand via passive or active measures, while ensuring that the occupants’ thermal and visual comfort can be achieved is a subtle balance of conflicting requirements and inter-dependent factors that façade design needs to fulfil.

FMDC’s highly skilled and experienced building physics team can efficiently assess all aspects of façade performance that influence energy and comfort. Our strategy for identifying the right solution for each project is based on striving to find to the simplest possible design that allows all requirements to be met. Conscious that collaboration between architect, building services engineer, and façade engineer is the key to a successful holistic approach, we place great value in establishing and maintaining mutual trust within design teams and with key collaborators.

In an effort to further expand our services, in recent years FMDC formed a strategic alliance with Inform Design, a Swedish-based specialist practice who supports our work with advanced parametric energy modelling of façades. This allows us to evaluate large sets of options, quantify their impact on solar gains, daylighting, and internal comfort, and develop mitigation strategies. Another service that we can offer through Inform Design is the accurate modelling of complex façade systems such as double skin façades or CCFs.